Professional Helmet Manufacturer

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality.

OEM Processes

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

Color

Material

Helmet styles

We need customized firefighting apparel

Start Customization

production processes

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

-

01Style SelectionThe first step in the production of fire helmets is style selection. This involves determining the design specifications that the helmet must meet, including shape, color, size, and any additional features such as integrated face shields or communication devices. This phase requires collaboration between design teams, safety experts, and end-users to ensure the helmet meets both aesthetic preferences and stringent safety standards.

-

02Injection MoldingOnce the style is finalized, the helmet shell is produced using injection molding. High-performance thermoplastics or composite materials are melted and injected into precision molds to create the helmet’s outer shell. This process ensures that the helmet is both lightweight and strong, offering the necessary protection against impact and penetration.

-

03Raw Material InspectionBefore assembly, all incoming raw materials, including the plastics, foam padding, straps, and other components, undergo rigorous inspection. This step ensures that all materials conform to the required safety and quality standards, with particular attention paid to their durability, resistance to heat and chemicals, and overall integrity.

-

04AssemblyDuring the assembly process, the molded shell is combined with other critical components such as the inner padding, chin straps, visor, and any additional accessories. Skilled workers meticulously assemble each helmet, ensuring that every part is securely attached and that the helmet provides both comfort and maximum protection to the wearer.

-

05Process InspectionThroughout the assembly process, various in-line inspections are performed to ensure quality and consistency. These inspections include:

●Shell Integrity: Checking for any defects or weaknesses in the molded shell.

●Component Fit: Ensuring all components are properly fitted and aligned.

●Chin Strap Security: Testing the chin strap’s attachment and adjustability.

●Overall Helmet Balance: Ensuring the helmet is balanced and comfortable to wear.

-

06PackagingOnce assembly and process inspections are complete, the helmets are carefully packaged. The packaging process includes placing the helmets in protective materials to prevent damage during shipping. Each package is also labeled with product details and includes necessary documentation such as user guides and safety certifications.

-

07Out-of-House InspectionAfter packaging, a batch of helmets undergoes out-of-house inspection to verify their compliance with national and international safety standards. This rigorous testing includes:

●Impact Absorption Performance: Testing the helmet’s ability to absorb and dissipate force from impacts.

●Penetration Resistance: Ensuring the helmet can withstand penetration by sharp objects.

●Combustion Resistance: Verifying the helmet’s resistance to flames and high temperatures.

●Chin Strap Flame Retardant Performance: Testing the flame retardancy of the chin strap.

●Mask Flame Retardant Performance: Ensuring any integrated mask or visor also meets flame retardant standards.

●Heat Resistance: Confirming the helmet’s ability to withstand prolonged exposure to high temperatures.

●Electrical Insulation Performance: Testing the helmet’s ability to protect the wearer from electrical hazards.

-

08DeliveryAfter passing all inspections and testing, the helmets are prepared for delivery. They are loaded onto transport vehicles and shipped to distributors, retailers, or directly to end-users. Each shipment is tracked to ensure it arrives on time and in perfect condition, ready to provide critical protection to firefighters in the field.

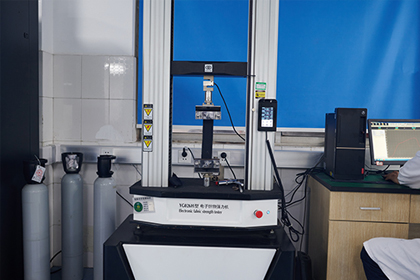

Professional And Advanced Production Equipment

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

Research and Development Strength

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality. The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products. The product application range involves: urban fire protection, forest fire protection, transportation, earthquake, civil air defense, military, civil, coal, petrochemical and other fields.

quality control

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality. The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products. The product application range involves: urban fire protection, forest fire protection, transportation, earthquake, civil air defense, military, civil, coal, petrochemical and other fields.

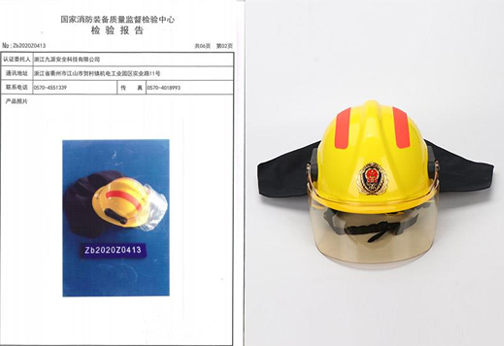

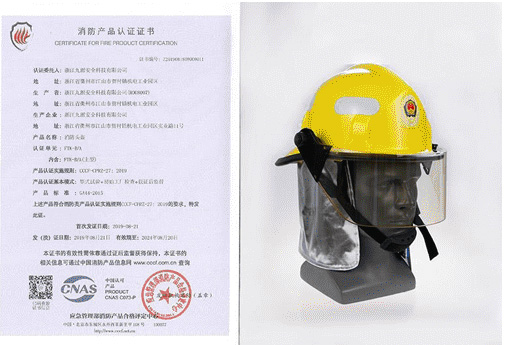

Qualification Certificate

With a keen focus on cutting-edge design and manufacturing practices, Triple is poised at the forefront of pioneering advancements, poised to redefine industry standards and cater to the evolving needs of our discerning customers.

Quick Consultation

We are looking forward to providing you with a very professional service. For any

further information or queries please feel free to contact us.