Professional Firefighting Clothing Manufacturer

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality.

OEM Processes

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

Gas Cylinder Capacity

Gas Cylinder Valve

Gas Cylinder Material

Pressure Reducing Valve

Pressure Gauge

Gas Supply Valve

Mask

Head-up display device

Back panel

We need customized firefighting apparel

Start Customization

production processes

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

-

01Injection MoldingThe first step in the production process involves injection molding, where high-strength plastic materials are melted and injected into precision molds to form critical components of the respirator, such as the face mask and back panel. This process ensures that each piece is molded with exact dimensions and structural integrity to meet safety standards.

-

02Accessory SewingIn the accessory sewing process, durable, flame-resistant fabrics are stitched together to create harnesses, straps, and other supportive elements of the respirator. Skilled technicians use industrial sewing machines to ensure that all seams are reinforced and that the accessories meet the required specifications for strength and comfort.

-

03Raw Material InspectionBefore assembly begins, all raw materials, including plastics, fabrics, and metal components, undergo a thorough inspection. This step is crucial for ensuring that only high-quality materials are used in production. Inspections focus on material integrity, compliance with safety standards, and consistency in quality.

-

04AssemblyThe assembly process involves carefully fitting together the various molded components, sewn accessories, and other critical parts such as the breathing valve, gas cylinder, and back panel. Skilled technicians follow detailed assembly instructions to ensure that each respirator is built to precise specifications, maintaining the integrity and functionality of the product.

-

05Process InspectionMultiple inspection stages are integrated into the assembly process to ensure product quality. These inspections include:

●Back Panel Appearance: Visual inspection for any defects or imperfections in the molded back panel.

●Bottle Valve Assembly: Verification that the valve is correctly installed and functional.

●Gas Cylinder Air Tightness: Testing the gas cylinder for leaks to ensure airtight integrity.

●Connection Strength: Checking that all connections and joints are secure and can withstand the required pressure.

●Whole Machine Air Tightness: Comprehensive testing of the entire respirator unit for any potential air leaks to ensure optimal performance. -

06PackagingAfter passing all inspections, each respirator is carefully packaged. The packaging process includes placing the product in protective materials to prevent damage during transportation, and ensuring that all necessary documentation, such as user manuals and safety certifications, are included.

-

07Factory InspectionBefore the respirators are released for distribution, a final factory inspection is conducted. This final inspection covers:

●Whole Machine Air Tightness: A repeat of the air tightness test to confirm the respirator's integrity.

●Air Supply Valve Performance: Ensuring that the air supply valve operates smoothly and delivers the correct airflow.

●Pressure Reducer Performance: Testing the pressure reducer to ensure it functions correctly under various conditions.

●Safety Valve Performance: Verifying that the safety valve activates as expected, providing an essential fail-safe mechanism.

Professional And Advanced Production Equipment

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales.

Research and Development Strength

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality. The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products. The product application range involves: urban fire protection, forest fire protection, transportation, earthquake, civil air defense, military, civil, coal, petrochemical and other fields.

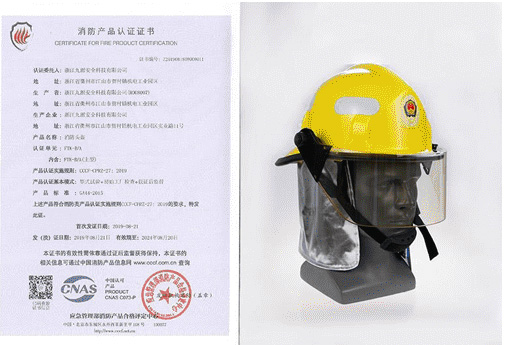

quality control

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff. Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality. The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products. The product application range involves: urban fire protection, forest fire protection, transportation, earthquake, civil air defense, military, civil, coal, petrochemical and other fields.

Qualification Certificate

With a keen focus on cutting-edge design and manufacturing practices, Triple is poised at the forefront of pioneering advancements, poised to redefine industry standards and cater to the evolving needs of our discerning customers.

Quick Consultation

We are looking forward to providing you with a very professional service. For any

further information or queries please feel free to contact us.