Fire Breathing Apparatus Series

A Self-Contained Breathing Apparatus (SCBA) is a lifeline for firefighters and other emergency responders operating in environments with hazardous or oxygen-deficient atmospheres. It provides a portable supply of breathable air, independent of the surrounding atmosphere.

-

JP-MF4 self-rescue respiratorSCBA Mask PPE Breathing Large Visual Field Low Weight Gas Mask Rescue for Firemen Chemical Industry Scientific Treatment

JP-MF4 self-rescue respiratorSCBA Mask PPE Breathing Large Visual Field Low Weight Gas Mask Rescue for Firemen Chemical Industry Scientific Treatment

Why choose us

Our mission is to make firefighting and frontline jobs safer and easier, around the world. We know there’s more to a suit than how much it can protect from heat. We’re committed to developing and working on new technologies in our kit, so it works for every body it protects.

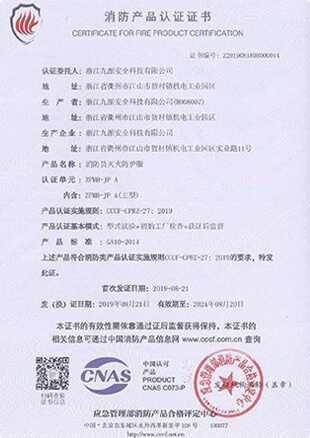

Qualification Certificate

With a keen focus on cutting-edge design and manufacturing practices, Triple is poised at the forefront of pioneering advancements, poised to redefine industry standards and cater to the evolving needs of our discerning customers.

Zhejiang Jiupai Security Technology Co., Ltd.

Zhejiang Jiupai Safety Technology Co., Ltd. is located in Jiangshan City, Zhejiang Province. It is a professional fire-fighting equipment and fire-fighting equipment manufacturer integrating production and sales. The company occupies more than 7,000 square meters and has 150 staff.

Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality.The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products.

Each product has an independent professional production workshop, a professional testing laboratory, and various testing equipment to ensure product quality.The main products of the company are: all kinds of firefighting clothing, chemical protective clothing, heat insulation clothing, firefighting gloves, firefighting belts, fire helmets, safety ropes, fire ladders, escape masks, rescuers, warning lights...also available On-demand customization requirements for various products.

Frequently Asked Questions

We have a certain scale capacity to ensure your order delivery cycle.

-

Can you provide sample?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

What is your terms of payment?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

What are your company's main products?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

After more than ten years of development ?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

What are your company's main products?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

What is your terms of payment?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

-

We have a certain scale capacity to ensure your ?Small samples in stock and can provide the samples for free. Customized samples will take about 5-7 days. Customer should take care shipment cost.

Request A Quote

Quick Consultation

We are looking forward to providing you with a very professional service. For any

further information or queries please feel free to contact us.